Industry experts weigh in on the future of maintenance, repair, and overhaul (MRO)

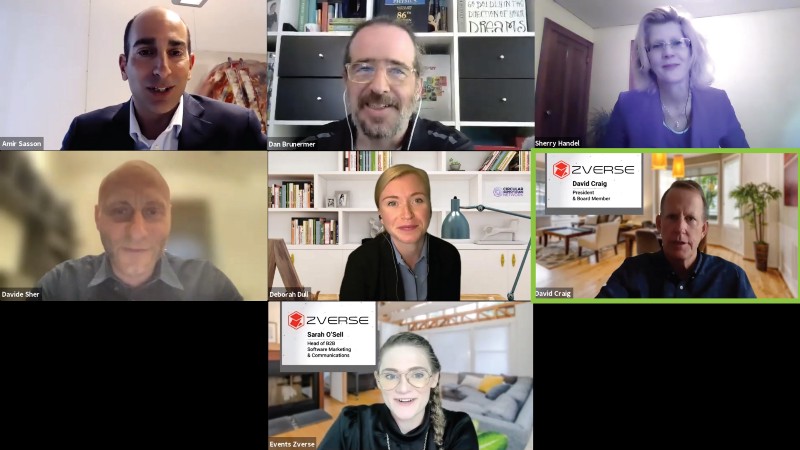

On June 1, 2021, ZVerse, along with media partner 3dpbm, hosted a virtual event featuring industry experts discussing the top 5 digital manufacturing and supply chain trends that are enabling on-demand maintenance, repair, and overhaul (MRO).

Experts from Circular Supply Chain Network, BI Norwegian Business School, ExOne original equipment manufacturer (OEM), and the Additive Manufacturer Green Trade Association covered industry research, strategy, and solutions, along with networking opportunities. ZVerse president, David Craig, also gave a first-look demo of ZVerse’s 2D to 3D technology.

Read on and watch to learn about the top 5 trends;

- Digital inventory will reduce physical spare part inventory stock with big material & capital savings.

- Local production — global production is going local with digital manufacturing for repair part production.

- Materials, parts, and equipment have lifetime value.

- Systems thinking — business systems will enable economic opportunity.

- Automation, paired with digital inventory, local production, lifetime value, and systems thinking, will enable on-demand MRO.

Delivering on MRO Event Highlights

Catch up on highlights from the event with the chapter-linked videos below.

ZVerse Welcome & Introduction: Top 5 Trends Enabling On-Demand MRO

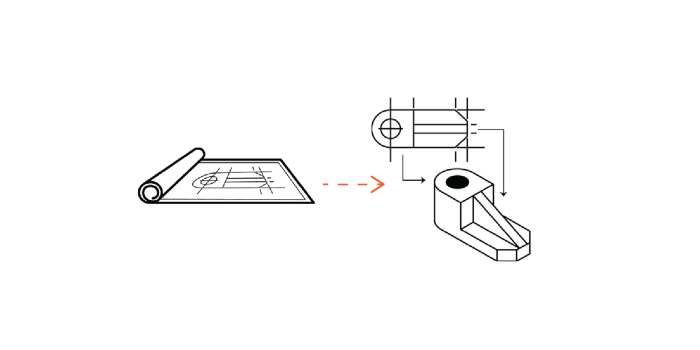

David Craig, President of ZVerse, introduces the top 5 trends enabling on-demand MRO and gives a first-look demo of ZVerse’s recently announced 2D to 3D technology. Industrial enterprises and OEMs are currently overstocking physical spare part inventory stock in order to meet on-demand repair needs. This has resulted in annual spare part inventory capital and material waste of 20–30%. Converting physical inventories to digital part libraries and leveraging local production opportunities with digital manufacturing has massive savings potential.

David also addresses circular economy material cycles and business systems opportunities to capture value in the repair market. Spare parts have historically been communicated for traditional manufacturing with paper or PDF 2D engineering drawings. The lack of 3D assets for digital manufacturing is a blocker to supply chain digital transformation. ZVerse’s automation-assisted engineering technology is positioned as a rapid solution for creating the 3D assets necessary to enable local digital manufacturing for on-demand MRO.

Trend 1: Digital inventory will reduce physical spare part inventory stock with big material & capital savings.

Deborah Dull, Founder, Circular Supply Chain Network calls attention to all the materials and things around us, asking the audience to consider that “In a circular economy, everything is inventory, and all the inventory out in the world was put there by a supply chain professional.” The ability to track materials and parts through digital inventories will enable organizations to tag, monitor, capture, value, and manage materials and things through their use cycles and lifetimes. Her organization brings supply chain professionals together to innovate around these topics.

Attend Circular Supply Chain Network upcoming events.

Trend 2: Local production — global production is going local with digital manufacturing for repair part production.

Dan Brunermer, Technical Fellow at ExOne, discusses how materials, machines, and parts will be produced moving forward at a local level using digital manufacturing technologies like 3D printing, in addition to some challenges related to education, financing, and sustainability. He also reviews an example of parts that original equipment manufacturer (OEM) ExOne’s binder jet 3D printing machines have produced for MRO with the US Navy. While 3D printing can directly produce parts, other opportunities include rapid mold and tooling production, as well as software solutions for eliminating excess trials and waste in prototyping for production.

Review ExOne’s Maintenance, Repair, and Overhaul (MRO) part case study.

Trend 3: Materials, parts, and equipment have lifetime value.

Sherry Handel, Executive Director of the Additive Manufacturer Green Trade Association (AMGTA) recently released a report on the sustainability aspects of metal additive manufacturing. An important consideration for production of any part moving forward is lifetime impact and value. In this segment, Sherry discusses her organization’s life cycle assessment (LCA) discoveries for metal additive manufacturing, where the production technology is most effective for reducing emissions, and next steps for the industry to build on this first-of-its-kind research.

Read Additive Manufacturer Green Trade Association additive metals life cycle assessment (LCA) research.

Trend 4: Systems thinking — business systems will enable economic opportunity.

Amir Sasson, Provost of the BI Norwegian Business School, reviews his studies on the economics of future manufacturing systems, advocating for the creation of regional manufacturing supercenters. As demand for customization and spare part production increases, batch size needed for production reduces, making agile technologies like digital manufacturing more economical at a local level. Delivering on this new economy will require the collaboration of multiple supply chain stakeholders including industrial enterprise, OEMs, service bureaus, field technicians, and even users.

Check out Amir Sasson’s research on digital manufacturing super centers & supply chain economics.

Trend 5: Automation, paired with digital inventory, local production, lifetime value, and systems thinking, will enable on-demand MRO.

Automation technologies are revolutionizing manufacturing. Solutions like ZVerse’s 2D to 3D automation-assisted engineering technology open opportunities to speed digital transformation initiatives. Once 3D spare part assets are created from legacy 2D PDF and paper files, a process called “reverse engineering”, they can be stored in a digital inventory. Field technicians can then order parts and quote individual part production with local digital manufacturing partners. Spare parts can be produced and delivered as needed, anywhere in the world for on-demand MRO.

All of the speakers at this event were featured in media partner, 3dpbm’s Sustainability eBook!