ZVerse is Assessing and Reducing Technical Debt in Design and Manufacturing — ZVerse 3D Solutions

Technical debt is not on your balance sheet, not addressed on your roadmap and often an afterthought, but ultimately can be the difference between executing swiftly and being paralyzed as you scale, grow and support your product(s). Technical debt is the cost of design decisions made that do not position your product for future growth.

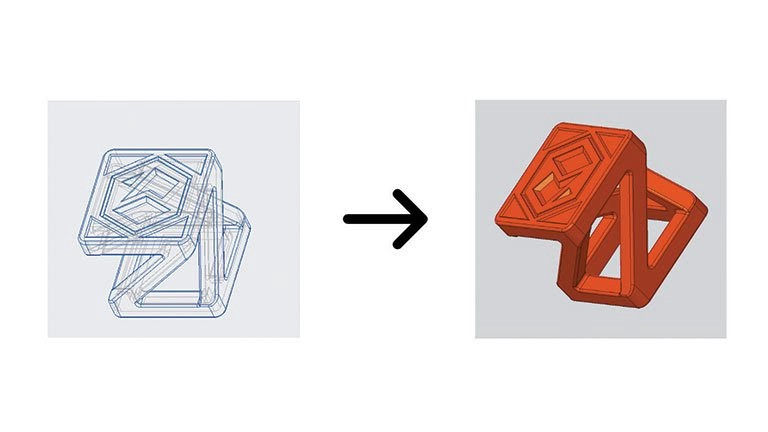

Converting 2D-CAD to 3D-CAD files at scale remains the roadblock standing in the way of the digital manufacturing journey for legacy and MRO parts. ZVerse’s automated solution removes this obstacle, ushering these parts into the digital manufacturing realm at a lower conversion cost and faster timeframe.

Most of my career has been at the intersection of mechanical engineering, software engineering and material science. Sitting at the intersection has given me a look into the differences between the development processes in each discipline. While there is good cause for significant differences in development workflows, I believe each could benefit from adopting patterns from one another.

In the world of software development, technical debt is an “early and often” consideration as engineers determine how to best structure data and systems to support future development. In doing so, they avoid future rework as they add new features and modules to their product. In addition, to the extent that it is possible, they also avoid creating assets and data structures that are unusable as entirely new products are created.

Where does technical debt come from?

Assets Depreciate as the World Evolves

Just like any asset you own, if left unmaintained, design and manufacturing assets eventually become debt as the world around them evolves. If you have ever sent a legacy 2D-CAD file to an on-demand manufacturing company only to find out they would not quote your work without a 3D-CAD file, you may have experienced how paralyzing technical debt can be. The reality is, oftentimes, addressing this type of debt is not a priority until you are in a situation like this, where you need a mission-critical part manufactured that was designed 30 years ago and is only saved in a 2D format. It is at this point of need that you have to decide whether to redesign the part in 3D, manually, ask a partner to do so or attempt to find a different vendor that will accept and quote the work as-is. For a mission-critical component, this process can mean losing tens of thousands of dollars in productivity or worse.

2D-CAD files are not the only form of technical debt that may be living in your design and manufacturing assets. For example, assets that do not contain full definitions for a product, post-processing requirements that are not called out, lack of interoperability requirement callouts and many more are all forms of technical debt that may accrue in your assets and result in manual work that will be repeated time and again when assets are put to use without a system and process in place to update/maintain these assets.

Processes Can Lead to Technical Debt

Development and business processes can unknowingly be a source of compounding technical debt. Arguably, this is a higher-risk form of technical debt than asset depreciation as this debt accrues systematically. In addition to occurring systematically, this debt tends to build on top of other debt because it is built into a process that is recurring in your organization. Process-driven technical debt can include things such as: lack of continuity between product requirements and user needs, unclear interoperability requirements, lack of a roadmap, inconsistent DFM requirements, unrecorded group knowledge, lack of input from stakeholders in the process and many more. Given these process failures, technical debt is often allowed to accrue, unchecked and compounding. Ultimately, this leads to assets that will depreciate further over time as the organization around them evolves or assets that will need to be recreated entirely as more information is presented that was not captured in process.

How You Can Assess Technical Debt in Your Organization

Design and manufacturing assets are a great starting point when assessing where technical debt exists in your organization. Not only can you quickly determine any technical debt that may be associated with your assets directly, but if you follow the chain of ownership of the assets, you can backtrack the processes that were gone through that allowed the debt to either be created, accrue or persist.

When assessing an asset or process for risk of technical debt, it is helpful to look for the following characteristics:

- Extensibility: Is there anything standing in the way of extending the function of a given part or assembly? Does this process support extending to new variables?

- Scalability: Is the asset able to scale in production with the details provided? Can this process scale without generating assets that carry technical debt?

- Maintainability: Is this asset something that can be maintained to support future processes and development?

While these are important factors to consider when assessing technical debt, there may be many other factors that make an asset or process prone to creating or holding technical debt. I would highly recommend considering any factors that might impact this in your organization.

Addressing Technical Debt

Although there are many ways to address technical debt that are specific to each individual organization, there are some overarching paths you might want to consider. For example, if you have identified a significant backlog of technical debt in legacy assets such as 2D-CAD files, it is important to prioritize those assets by risk of need and begin converting those files into assets that give you maximum optionality for production or design rework. This way you never find yourself in the tough position of “paying off” debt when you desperately need a part or design change. For example, the quickest and most cost-effective way to transition that debt off of your CAD asset balance sheet is to find, assess and convert those assets into 3D-CAD models using advanced automation.

Aside from lingering technical debt on assets, if you identify processes that are generating technical debt in your organization, it is important to re-engineer processes to work as much of this out of the process as possible. To ensure key processes are not generating technical debt, you might want to make sure the following are in place: good model-based definition practices, strong organizational use of PLM/PDM tools, organizational use of tools that capture input from all stakeholders early in processes, a transparent roadmap, the use of a strong DME (Digital Manufacturing Enablement) platform, and many more tools and processes that can all be good for helping to reduce technical debt.

Originally published at https://www.zverse.com on March 8, 2021.