ZVerse On-Demand Design Case Study: ZShields™

When market urgency demands rapid response ZVerse is here to help.

In the course of about two weeks in March 2020, ZVerse started receiving requests from hospitals and government agencies pleading for ventilator components, face shields, and masks. The team at ZVerse was uniquely prepared. Since 2013, the company has built a reputation for speedy product development with trustworthy quality by offering On-Demand Design services, formerly known as CADaaS (Computer-Aided Design as a Service), consisting of an in-house and distributed designer and engineer network. Recognizing the urgency of the situation, the team reached out to a talented designer in the network, Scott Henderson, and over the course of the next four months, brought ZShield PPE to market.

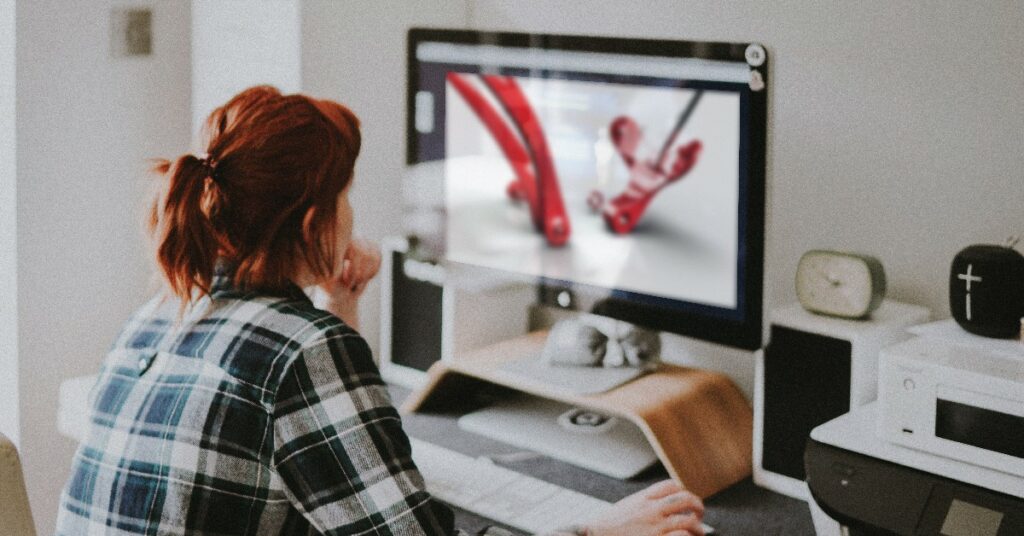

The ZVerse On-Demand Design Process:

Henderson worked with ZVerse’s team and industry connections to understand the safety and user requirements for PPE products. Face shields were positioned early in the pandemic as a head-mounted facial cover which can block 92–96% of cough-misted virus particles from reaching others around the wearer. This effort pointed to the unmet need of a neck-mounted shield model for low-risk environments. Identified product users included service workers and those in the public or government sphere who already wear head-mounted devices for their jobs, require upward visibility, need to have their face fully visible in their job, or hair and makeup uninterrupted.

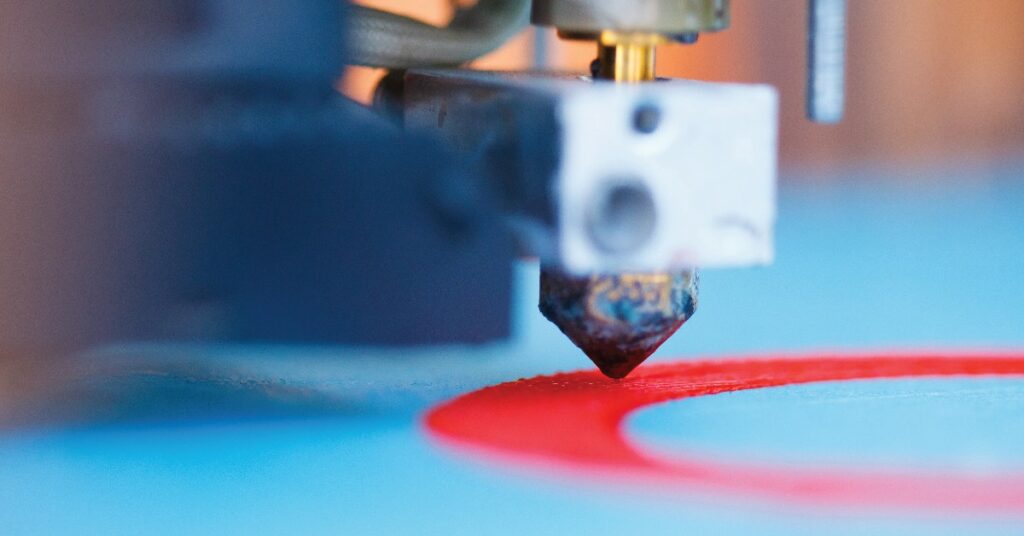

ZVerse leverages digital manufacturing tools including 3D printing to speed product development time by 33%.

3D printing is an “additive manufacturing” process where material is applied in layers to build an object out of plastic, metal, or other materials according to computerized directions. ZVerse leveraged 3D printers to iterate quickly, testing prototypes immediately on staff and at local hospitals.

“The design process behind ZShield Flex was design as it should be,” Henderson said. “Each morning ideas were discussed and the remaining daylight was spent modeling a new 3D CAD that we would then 3D print overnight to be ready by the following morning.”

Scott Henderson – Product Designer

Over 3000 emails, 200 hours on Zoom, 75 design reviews, and collaboration with 15 stakeholders, the team brought ZShields to market in only four months, 33% faster than the typical six month consumer product design cycle. During a time of extreme global supply chain disruptions and adjustments to working from home, the ability to pair creativity and intellect with local digital manufacturing capabilities ensured ZVerse was first to market at peak demand.

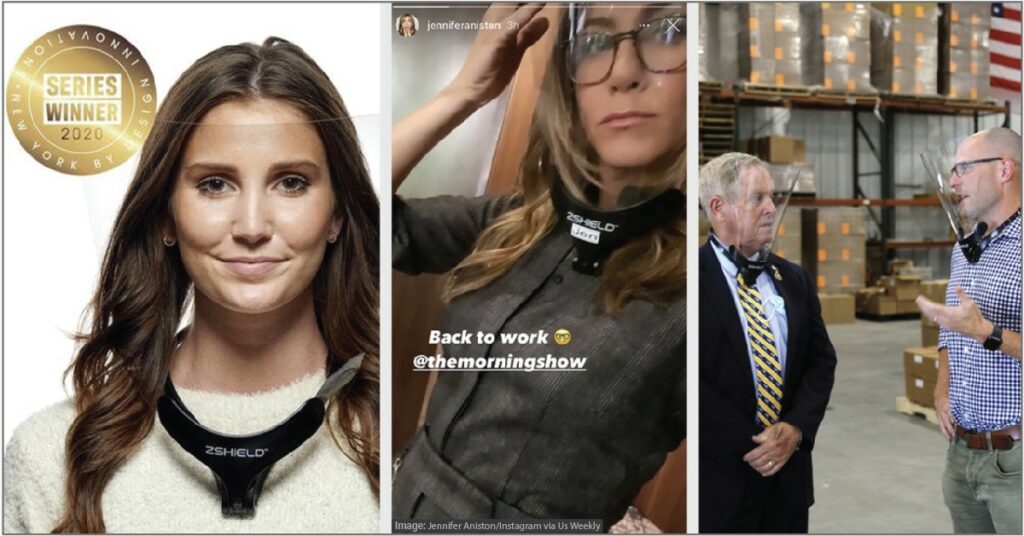

From Hollywood to Congress, consumers and the global design community applaud ZShield.

ZShield exploded in the marketplace, with features on ABC’S Shark Tank, the Today Show, New York Magazine, Condé Nast Traveler, US Weekly, and more. Celebrities including Jennifer Aniston, Matt Damon, Brad Pitt, Halle Berry and legislators including Lindsey Graham donned the product as they returned to work. ZVerse scaled ZShield to produce millions of units with onshore manufacturing in Thomasville, North Carolina, USA. ZShield won two 2020 Fast Company Innovation By Design Awards, was the winner of the New York By Design CBS special, featured in the New York Times, and received a notable honor at the 2021 Core77 Design Awards.

Buy ZShields and other PPE products at: zshield.com.